Product benefits

Product characteristics

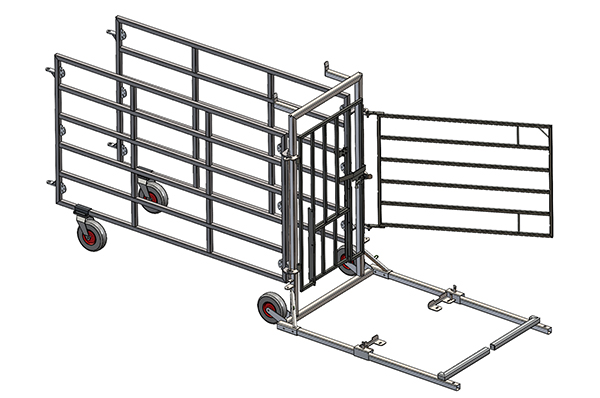

The KVK Model 650-SP2 is an on-farm solution that is easy and simple to operate, while at the same time giving you the feeling of working like a professional. The chute is developed and designed to meet today’s growing demand for hoof trimming, while providing a high comfort to the hoof trimmer and livestock during the hoof trimming. The 650-SP2 is designed to perform hoof trimming of livestock between 200-900kg.

The KVK hoof support system

The unique KVK hoof support system provides a rigid surface to trimming against allowing for the hoof trimmer to use both hands for optimal workflow and more precise trimming. The hoof support plates can be manually adjusted in length and heigh making sure the hoof is support in the best way possible, which is important in the treatment or application of a block on the hoof.

Essential hydraulic functions

The model 650-SP2 is equipped with the essential hydraulic functions. The legs of the cow are lifted with help from the hydraulic winches and placed on the hoof support plates. During the lifting process the leg sleeves allow for an easy and gentle fixation. The hydraulic double belly band system provides comfort and stability for the livestock during treatment. The double belly band system also offers the possibility of using the chute for other treatment purposes.

Easy and simple to operate

The design of the 650-SP2 with a hydraulic lifting system, which can be individually adjusted, provides you with a good working posture during the trimming – making it easier for you to trim for longer periods of time. The chute is equipped with rubber plates under the feet, which makes it very stable and help reduce noise.

The side-hinged backdoor is designed to be part of the barrier when guiding the livestock into the chute, while open it blocks the flight route of the cow to the right side. At the same time the side-hinged back door enables the usage of the back door for storage purposes creating an easy access to the equipment needed for trimming such as knives, bandages etc.

The four LED working lights placed above all hooves gives a great view of the working area during the trimming, which is very important in the detection of illnesses.

Easy maintenance

The hoof trimming chute model 650-SP2 is fully galvanised making the surface of the chute very durable and therefore very resistant towards aggressive environments, which can be found on farms.

The floor of the chute is covered in a special rubber mat, which is very durable and made of a material which can withstand the usage of strong cleaning detergents. Furthermore, the rubber mat is designed with a non-slip surface and a technology the absorbs the weight of the cow into the mat, making it ideal for securing the footing of the cows.

The back of the floor is designed with a grid, so that faeces will not accumulate on the floor of the chute making it slippery and securing that the hoof is not covered in faeces and making it cleaning-friendly.

Animal welfare

The 650-SP2 is developed and designed on the basis of the anatomy and movement of the cow, trying to make the chute as suitable as possible for the livestock undergoing trimming. Therefore, animal welfare and comfort have and will always be one of the key values in our development of our hoof trimming chutes.

On this basis, the manual front gates are designed to “catch” the animal in its movement into the chutes, while the gates open from the inside towards the outside. Therefore, the animal is not stopped abruptly in its movement. The opening and closing of the front gates are done manually by using the two different handles placed on top of the chute above the front gate. Furthermore, the front gate is individually adjustable in width, so it fit both smaller and larger livestock.

The front and back leg suspension are placed at an angle, which takes the cow’s natural movement into account and therefore does not put extra strain on joints and tendons, because it doesn’t force the cow’s legs into extreme positions.

All components on the chutes are handpicked to minimize noise, this can help reduce the stress levels for the cow, which creates a better cow-flow and working environment for cow and hoof trimmer.

Technical information

The 650-SP2 hoof trimming chute is CE approved, while it meets the strict requirements of the Machine Directive:

- Directive 2006/42/EC-

- Annex I Essential Health And Safety Requirements

- S/EN 60204-1

- DS/EN ISO 13849-1

- Directive 2004/108/EC

| A standard model 650-SP2 includes the following | |

| Hydraulic front winch | Optional extra |

| Front gate open/close | manual |

| Back door open/close | manual |

| Double belly band | hydraulic |

| Lifting/lowering of the chute | hydraulic |

| Leg winch all 4 legs | hydraulic |

| Adjustable hoof support plate (in/out, right/left) | manual |

| Individual working height | Yes |

| Mechanical brake | Optional extra |

| Led working lights | 4 pcs. |

| Heating cabinet | Optional extra |

| Hot-dip Galvanized | Yes |

| Transport wheels | 4 (2x front and 2x back) |

| Gallow with socket | Yes |

| Knife holders | 3 pcs. |

| Cup holder | 1 pcs |

| Hot air gun holder | optional extra |

| Rubber floor mat | Yes |

| Hoof support system | Yes |

| Socket | 2 pcs. |

| General information | |

| Length x width | 250 x 160 cm |

| Height with gallow | 210 cm |

| Lowest possible transport height | 210 cm |

| Height, lifted with gallow | 250 cm |

| Height on wheels | 230 cm |

| Standing length Front gate to backdoor Front gate to cross bar | 195 cm 175 cm |

| Weight | 840 kg |

| Maximum lifting capacity at 150 bars | Chute: 3000 kg Belly band (lift): 720 kg Belly band (hold): 1600 kg |

| Surface treatment | Hot dip galvanized |

| Livestock, optimal weight | 200-900 kg |

| Hydraulic and Electrical System | |

| Electrical Motor | 2,2 kW |

| Hydraulic Pump unit max operating pressure | 180 Bar |

| Hydraulic system working pressure | 30-150 Bar |

| Hydraulic Oil | Standard 32 |

| Electrical control | Individual adapted to country specifications |

Individual configuration

You can choose from a variety of extras such as cup holders, knife holders, rubber belly band, mechanical breaks for the legs etc. On our webpage ww.kvk.dk you are able to build your own chute, so it meets your wishes and requirements.

Further information

Functionality & animal welfare

The from KVK efficient choof fixation plate system supports the Hooftrimmer with the functional hoof care and protects the to be treated animal. The hydraulic Hoof fixation plates ensure that the hoofs are firmly fixed and the Hooftrimmer can look at the hoof from above. This enables a natural feeling of work.

Maintenance and correct handling

KVK has summarized all the information you need to handle this hoof trimming chute properly in a manual which is delivered with the machine.

The right spare parts always at hand

If you need spare parts or have questions about the chute, do not hesitate to directly contact your personal KVK contact person. A list of spare parts can be found here and can be ordered individually and quickly, either independently or by arrangement.