Product benefits

Product characteristics

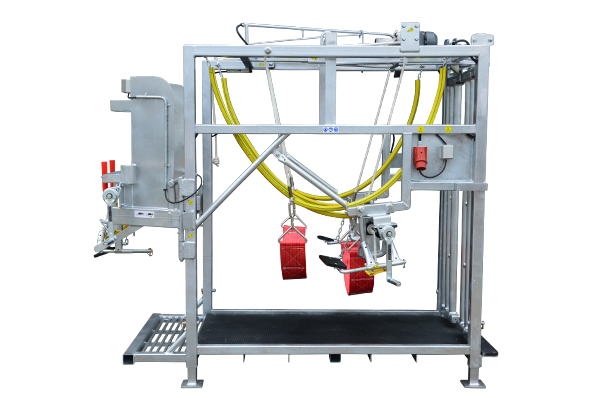

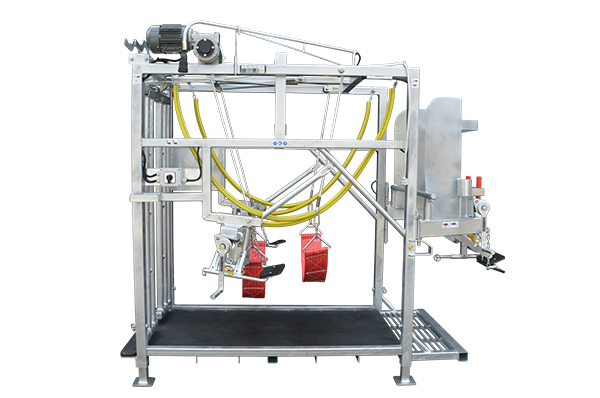

The KVK model 650-SP0 is an optimal on-farm solution for individual treatments, which will secure a simple, easy and reliable handling and operation. The chute is developed and designed to provide high comfort for the hoof trimmer and livestock during trimming. The 650-SP0 is designed to perform hoof trimming on livestock between 200-900kg.

The KVK hoof support system

The unique KVK hoof support system provides a rigid surface to trimming against allowing for the hoof trimmer to use both hands for optimal workflow and more precise trimming. The hoof support plates can be adjusted manually in length and height to make sure the hoof is supported in the best way possible, which is important in the treatment or application of a block or bandage on the hoof.

KVK’s Transport system

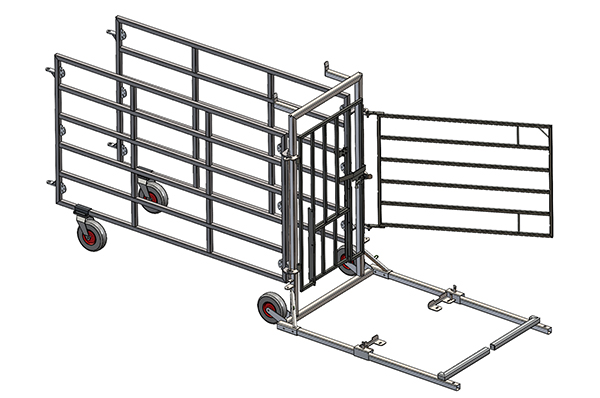

The 650-SP0 can easily be transported using the unique KVK transport system, where the leg sleeve is attached to the extra long arm of the wheel. When turning the hand winch the chute is lifted manually. To place the chute in the desired location just turn the safety handle the opposite direction and the chute will start to lower. This will make it easier to integrate hoof trimming into the daily work life and ensure a good solution for individual treatments.

Easy and simple to operate

The model 650-SP0 can be adjusted in 5 different heights settings, which provides the user with the possibility of a better working posture. When using the highest possible hight it is recommended that a ramp is built for a safer entry and exit of the cows.

The side-hinged backdoor is designed to be part of the barrier when guiding the livestock into the chute, while open it blocks the cows flight route to the right side. At the same time the side-hinged back door enables the usage of the back door for storage purposes creating an easy access to the equipment needed for hoof trimming such as knives, bandages etc. The top bar is designed as holder for the angle grinder.

Furthermore, the chute is built with a solid floor covered in a thick rubber mat. This means that the energy of the cow is contained inside the chute and not transferred to the floor. The weight of the cow is utilised to stabilize the chute and therefore reduce the possibility of moving the chute. This creates a safer work environment for the user.

Hand winch for lifting legs with an integrated break, which locks the leg sleeve in the current position. The safety handle also ensures that when using the KVK transport system, the handle won’t start turning on its own.

Animal welfare

The manual front gates are designed to “catch” the animal in its movement into the chute, while the gates open from the inside towards the outside. Therefore, the animal is not stopped abruptly in its movement. The opening and closing of the front gates are done manually by using the two different handles placed on top of the chute above the front gate or by using the front door rope at the back of the chute. This allows for the trimmer to walk the cow into the chute creating a low stress environment. Furthermore, the front gates are individually adjustable in width, so they fit both smaller and larger livestock.

The electrically powered double belly band system ensures that the cow is safely secured during the trimming. The belly band system is operated by a turning knob, making it simple to operate.

The front and back leg suspension are placed at an angle, which takes the cow’s natural movement into account and therefore does not put extra stain on joints and tendons, because it doesn’t force the cow’s legs into outer positions.

All components on the chutes are handpicked to minimize noise, this can help reduce the stress levels for the cow, which creates a better cow-flow and working environment for cow and hoof trimmer.

Technical information

The 650-SP0 hoof trimming chute is CE approved, while it meets the strict requirements of the Machinery Directive:

Directive 2006/42/EC:

DS/EN 60204-1:

DS/EN ISO 13849-1:

Directive 2004/108/EC

| A standard model 650-SP0 includes the following | |

| Front gate open/close | manual |

| Back door open/close | manual |

| Double belly band | electrical |

| Lifting/lowering of the chute | manual |

| Leg winch all 4 legs | manual |

| Adjustable hoof support plate (in/out, right/left) | manual |

| Individual working height | 5 individual fixed setting for height |

| Hot-dip Galvanized | Yes |

| Transport wheels | 2 pcs. |

| Gallow with socket | Yes |

| Knife holders | 2 pcs. |

| Cup holder | 1 pcs |

| Hot air gun holder | optional extra |

| Rubber floor mat | Yes |

| Hoof support system | Yes |

| Socket | 2 pcs. |

| General information | |

| Length x width | 250 x 145 cm |

| Height | 205 cm |

| Height lifted | 240 cm, with 5 individual fixed setting for height |

| Height on wheels | 202-210 cm |

| Standing length Front gate to backdoor Front gate to cross bar | 190 cm 175 cm |

| Weight | 500 kg |

| Belly band lifting capacity | Belly band (lift): 650 kg Belly band (hold): 1600 kg |

| Surface treatment | Hot dip galvanized |

| Livestock, optimal weight | 200-900 kg |

| Electrical System | |

| Electrical Motor | 1,1 kW |

| Electrical requirements | 3x400V / 1x230V |

Further information

Functionality & animal welfare

The claw fixation plate system from KVK efficient supports the trimmer with the functional hoof care and protects the animal. The hydraulic hoof fixation plates ensure that the hoofs are firmly fixed and the trimmer can look at the hoof from above. This enables a natural feeling of work.

Maintenance and correct handling

KVK has summarized all the information you need to handle this hoof trimming chute properly in a booklet which is delivered together with the chute.

The right spare parts always at hand

If you need spare parts or have questions about the chute, do not hesitate to directly contact your personal KVK contact person.

Find a list of spare parts and order her.